Waste prevention as the first priority in the waste hierarchy

Recyclability of packaging

The Verpackungsgesetz aims to promote eco-friendly packaging and high-quality recycling. These goals can only be reached if the packaging design is fit for high-quality recycling. This means that the availability of recycling technologies and capacities in actual waste management should be considered early on, when the packaging is being designed. Otherwise, the recycling targets defined in the Verpackungsgesetz cannot be met.

Recycling-friendly packaging design – what does that mean?

Recycling-friendly design within the meaning of the Verpackungsgesetz (Packaging Act) implies striving for maximum recyclability when designing and producing packaging. The goal is to keep the material used for production in a closed substance cycle, so that new material – ideally new packaging – can be created from a packaging that has been recovered or recycled.

This goal is to be achieved by fostering…

… recycling-friendly packaging design,

… the use of suitable materials,

… the incorporation of recyclates and

… production processes in line with the Verpackungsgesetz.

In other words: after use, packaging should be turned into a secondary product of the same material as much as possible.

Restrictions apply to the use of recyclates in food packaging made from plastics. Except for PET (polyethylene terephthalate), which is used in items like beverage bottles and thermoforming films, no other plastics are currently approved for food contact. The authority granting or refusing approval is the European Food Safety Authority (EFSA). However, it is possible that advances in packaging technology will allow the production of food packaging from recyclates other than PET in the medium to long term. The current restriction on the use of recyclates does not apply to other food packaging such as glass, where an average of 60 percent of the material used in production is recycled and has been for many years, with no official approval necessary.

What is the legal framework for recycling-friendly design?

As per section 23 (2) no. 1 KrWG (Circular Economy Act), parties who develop, produce or distribute a product bear producer responsibility. The goal is to produce reusable, durable products in a resource-efficient way. After use, these products should be suitable for proper, safe and high-quality recovery and environmentally friendly disposal.

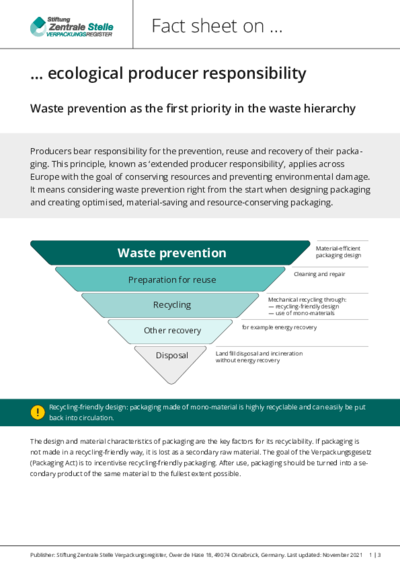

However, prevention is the top priority in circular economy law. Eliminating packaging, minimising the use of resources and reusing offer the greatest cost savings, making them the most attractive option for producers. The second priority is achieving the highest-quality recovery, which means focusing on recycling. The Verpackungsgesetz support this by requiring system operators to create financial incentives for recycling-friendly packaging design, encouraging the use of recyclates and renewable resources (section 21).

All of this is based on the minimum standard for determining the recyclability of packaging. The Zentrale Stelle Verpackungsregister (Central Agency Packaging Register – ZSVR) releases an updated version of this minimum standard on 1 September of each year, in consultation with the German Environment Agency.

From recycling-friendly packaging design to high-quality recovery

Closed substance cycles require that the raw materials used in packaging and their combinations are recyclable. Find out more about the goals and benefits of recycling-friendly design and explore positive packaging examples.

Benefits of recycling-friendly design

Sortability and recyclability in practice

The possibility to reprocess into high-quality recyclates

Closed cycles: better availability of recyclates for own packaging

Environmental protection by safeguarding resources and reducing carbon emissions

Support towards a modern circular economy

Potential energy and materials savings

Goals

Promoting and advancing recycling-friendly design along the entire value chain

Use of recyclates

Optimising packaging design, including material characteristics and colours

Minimising the quantity of materials required to make the packaging

Optional single-variety processing of packaging materials

Conclusion

Recycling-friendly packaging design helps take pressure off the environment.

Packaging is a resource

Positive packaging examples for determining recyclability

This image shows white, uncoloured PP/PE mono-material packaging, which offers a high degree of recyclability. It is easy to separate from other packaging (and allocate to a dedicated recycling path) as white material will absorb near infrared (NIR) light. As it is recognisable as PE or PP in the sorting process, white mono-material packaging with a relatively small label offers a high degree of recyclability. The recycling process can turn the white packaging into pellets, which then can be coloured as desired.

This image shows sortable packaging that has either no labels or only small labels, so that sorting machines can easily identify the material. A general note on labels and sleeves: the smaller the label or the sleeve on any given packaging (< 50 percent), the more probable it is that the sorting machine will identify the packaging correctly. Bottles and cans made from a single material, such as PP, PE, PS or PET-A, would in theory offer a high degree of recyclability based on the material alone. However, if they bear too large a label, they cannot be allocated to the right recycling path, which reduces their recyclability in practice to zero. The allocation also depends on the combination of material types used for label and container.